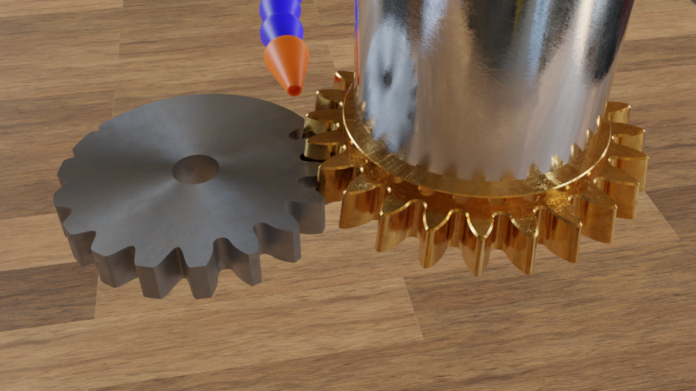

Manufacturers of the gear shaper cutters help to provide full gear shaping operation. This may refer to being a process involving continuous and rotational cutting centered on the same path. It is also referred to as the most accurate cutting process, which will help to develop both internal and external teeth behind the surface finish. The shape is base on the cutter motion installed on a cutter spindle, and the gear board placed on the job spindle bracket. Both are empowered by the individual warm and colder wheels that enable gears to shift for the cutter-work partnership.

This concept can help to generate different types of gears, including spurs, helical, splines, and herringbones. This principle often provides gears that have developed to greater flexibility, which also permits them to produce teeth near to the shoulders that any such strategies cannot offer. There are primarily two major categories of shaper cutters that involve the formation of the shank and the form of a disk. For the restricted area provided by the work piece, the shank style cutter is very useful in the case of the tapered shank for entering the narrower bores.

The style of the disk is much more popular and is the most stable of both choices available. The disk style variant is known as the template cutter, which is very handy for the half-inch plate. They are more widely seen in external teeth implementations, along with various forms of internal applications. Depending on the duration and form of the work piece, the adapters may also be included in this method.

The shape is based on the cutter motion installed on a cutter spindle, and the gear board placed on the job spindle bracket. Both are empowered by the individual warm and colder wheels that are coupled together to enable gears to shift for the cutter-work partnership. The method is strongly organized as the cutter tends to render consecutive passes across the entire blank, creating a set of various forms of individual cards that are tight-spaced. Such increasingly incremental passes often require a backward break and act to ease upwards.

The cutting motion in which the cutter and job must operate together in a meshed state is often regarded as through the downward ones. The job in the structures is often relaxed upon the upward return such that scratching is prevented on the cutter’s non-cutting sheet. The entire process continues until the work piece at inn feet depth rotates its self to 360 °.At this stage the 360 ° rotate should aid to continue with the fresh-cut in feet depth, which is dramatically brought into the work piece. When the cutter reaches the full depth, it produces the desired shape of the tooth. These types of cutters are important gears which help to provide clearance during the entire cutting cycle.

Hence, the gear shaper cutter designs provide a wide variety of choices to their buyers to choose from as per their need and help to undertake the process effectively and efficiently.