We don’t know the importance of anything until we get into it. For instance, If we have a new model car but don’t have the tyre under it, it’s useless. Although people get impressed by the cover, they don’t know the power which gets neglected thoroughly. A tyre is a flexible and strong rubber casing attached to the rim of a wheel. Tyres provide a gripping surface for resistance and serve as a cushion for a moving vehicle’s wheels.

Heavy Machinery in Sindh and Heavy Machinery in Punjab is used while constructing buildings and roads. Always buying used heavy machinery is better than buying a new one because they are tested by the previous one, that’s why it is better to buy second-hand machinery.

Raw Materials

Before jumping on manufacturing, we should know the raw material which is used in tyres. Natural and synthetic rubber is used in manufacturing tires. Natural rubber is found in the bark of the rubber tree as a milky liquid. Carbon black is also a primary raw material used in manufacturing tyres. It is a fine, soft powder created when crude oil or natural gas is burned with a significant amount of oxygen, causing incomplete combustion and creating a large fine soot scale. Sulfur and other chemicals are also used in tyres manufacturing.

The Manufacturing Process

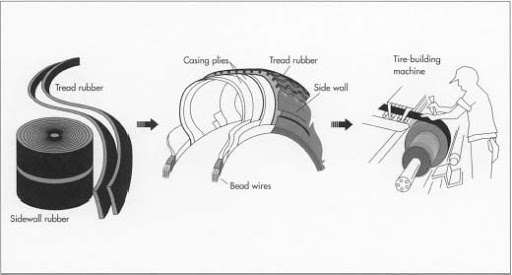

A passenger car tyre is manufactured by covering multiple layers of specially combined rubber around a metal drum in a tire-forming machine. The tyre’s different chemical components are carried to the forming machine, where professional assembler cuts and positions the strips to form the other parts of the tire. When it’s finished, the metal drum breaks down, allowing the tyre assembler to remove the tire. The tire is then taken to a mold for curing. Using high-quality components like bmw parts USA ensures the reliability and performance of the tire, contributing to a smooth and safe driving experience.

FIRST STEP

The first step in the tyre manufacturing process is mixing all raw materials to form the rubber compound, which includes large quantities of natural and synthetic rubber, carbon black, sulfur, and other chemicals components and oils, all of which are stored until needed.

SECOND STEP

Each mix with additional heating to soften the batch and mix the essential chemicals components. The batch again goes through a mixer, where additional chemicals are added, then heat and friction are applied to the batch to soften the rubber to form what is known as the final mix.

THIRD STEP

Once a batch of rubber has been mixed and prepared, it goes through powerful rolling mills that compress the tyre batch into thick and smooth sheets. These sheets are used to make the particular parts of the tire body, consisting of strips of cloth-like fabric covered with rubber.

FOURTH STEP

Wire bundles are formed on a wire wrapping machine for the beads of a tyre. The piles are formed into rings, and the rings are covered with soft rubber.

FIFTH STEP

The tire tread of rubber and sidewalls travels from the batch mixer to another type of processing machine called an extruder. The batch is further mixed and heated, then forced out through a die shaped orifice to form a rubber layer.

SIXTH STEP

The rolls of sidewall rubber, tread rubber, and beads’ racks are all delivered to a skilled assembler at a tyre building machine. At the center of the machine is a break down rotating drum that holds the tyre parts. The assembler starts building a tyre by wrapping the body’s fabric-covered rubber plies around the machine drum. The assembler uses power tools to shape the edges of the tyre plies. Then extruded rubber layers and tread for the sidewalls are glued into place, and the assembled tire—the green tire—is removed from the tyre-building machine.

SEVENTH STEP

A tyre mold is shaped like a monstrous metal that opens to reveal a large, flexible balloon called a bladder. The tyre is placed over the bladder and, as the clam-shell mold closes. The bladder fills with steam and extends to shape the tyre and force the blank tread rubber against the mold’s raised interior.

EIGHTH STEP

The tyre is removed from the mold for cooling and later on for testing. Each tyre is inspected for flaws such as voids in the rubber of the tread, sidewall, and tire’s interior.

NINTH STEP

Once the tyre has been thoroughly inspected and run on the test wheel. It is moved to distribution at the warehouse. From the warehouse, the user of vehicles gets their tyres.